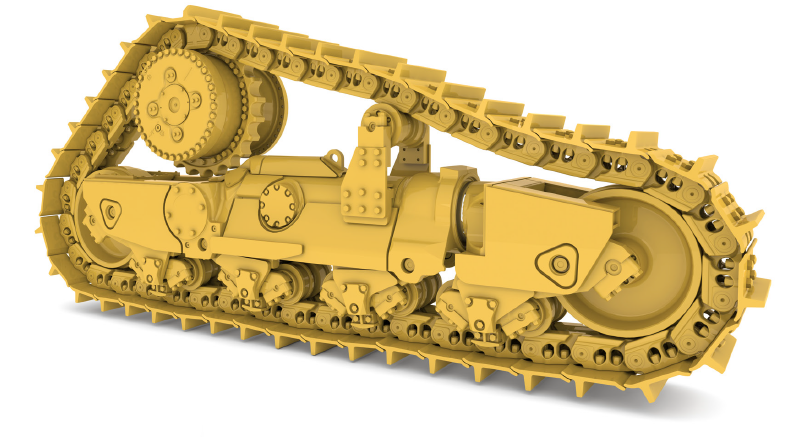

Hanyoyin warware matsalolin don kula da kullun da ke ƙarƙashin motar bulldozer

(1) Waƙar rarrafe tana kula da tashin hankali mai kyau

Idan tashin hankali ya yi yawa, tashin hankali na bazara na ɗigon rago yana aiki akan fil ɗin waƙa da bushing ɗin waƙa, da'irar fil ɗin waje da da'irar ciki na bushing ɗin an fuskanci babban damuwa na extrusion, da fil kuma Za a sawa bushing ɗin waƙar da wuri lokacin aiki.Ƙarfin na roba na bazara kuma yana aiki a kan shingen da ba shi da aiki da bushing, wanda ya haifar da damuwa mai girma na fuskar fuska, wanda ya sa bushing ɗin da ba shi da amfani ya zama sauƙi don niƙa zuwa wani yanki mai zurfi, kuma filin waƙa yana da sauƙi elongated, kuma zai rage aikin injiniya. ingancin watsawa da ɓarna watsawar injin zuwa sprocket da ikon waƙa.

Idan tashin hankalin waƙar ya yi sako-sako da yawa, za a iya raba waƙar cikin sauƙi daga mai aiki da abin nadi, kuma waƙar za ta rasa daidaitaccen daidaitawarta, wanda zai sa waƙar ta yi jujjuyawa, duka, da tasiri, wanda zai haifar da rashin lahani na rashin aiki. da abin nadi.

Ana yin gyare-gyaren tashin hankali na crawler ta ƙara man shanu zuwa bututun mai na silinda tashin hankali ko sakin man shanu daga bututun fitar da mai, da daidaitawa tare da la'akari da daidaitaccen izinin kowane samfuri.Lokacin da firar sassan waƙoƙin ya ƙaru zuwa wurin da ake buƙatar cire saitin sassan waƙoƙin, za a sawa saman haƙoran haƙoran tuƙi da kuma bushing ɗin waƙar da ta saba.An juyar da hannun riga, an maye gurbin fil ɗin da aka sawa fiye da kima da bushings ɗin waƙa, kuma ana maye gurbin taron haɗin gwiwar waƙa.

(2) Rike dabanzamatsayi daidaitacce

Matsakaicin rashin aiki yana da tasiri mai tsanani akan wasu sassa na hanyar tafiya, don haka daidaita rata tsakanin farantin jagora da firam ɗin waƙa (gyara kuskure) shine mabuɗin don tsawaita rayuwar hanyar tafiya.Lokacin daidaitawa, yi amfani da gasket tsakanin farantin jagora da abin ɗamara don gyarawa.Idan tazarar tana da girma, cire gasket;idan tazarar ta yi kadan, ƙara gasket.Matsakaicin izini shine 0.5 zuwa 1.0mm, kuma matsakaicin izinin izini shine 3.0mm.

(3) Juya fil ɗin waƙa kumawaƙa bushinga kan lokacin da ya dace

A yayin aikin fitin waƙa da bushing ɗin waƙa, a hankali farar waƙar yana ƙara tsawo, wanda ke haifar da rashin haɗin kai tsakanin motar tuƙi da bushing ɗin waƙar, wanda ke haifar da lalacewa ga bushing ɗin waƙar da kuma rashin lalacewa a saman haƙorin tuƙi. dabaran, wanda zai haifar da meandering, flapping, da tasiri.Rage rayuwar tsarin tafiya sosai.Lokacin da ba za a iya dawo da filin ta hanyar daidaita tashin hankali ba, ya zama dole a juya fil ɗin waƙa da bushing don samun daidaitaccen filin waƙa.Akwai hanyoyi guda biyu don tantance lokacin da ake juya fil ɗin waƙa da bushing ɗin waƙa;hanya ɗaya ita ce ƙayyade lokacin lokacin da filin waƙar ke tsawo da 3mm;Wata hanyar ita ce ƙayyade lokacin da diamita na waje na waƙar bushing ke sawa da 3mm.

(4) Tsarkake kusoshi da goro cikin lokaci

Lokacin da kusoshi na hanyar tafiya suka yi kwance, ana samun sauƙin karyewa ko ɓacewa, suna haifar da gazawa.Ya kamata a duba waɗannan kusoshi don kulawa na yau da kullun: ƙwanƙolin hawa na abin nadi na tallafi da abin nadi mai goyan baya, ƙwanƙwasa ƙwanƙwasa na toshe haƙoran haƙora, ƙwanƙwasa takalmin waƙa, ƙwanƙwasa ƙwanƙwasa na abin nadi, da kuma maƙallan hawa na kan takalmin gyaran kafa na diagonal.Koma zuwa jagorar koyarwa na kowane samfuri don ƙara matsa lamba na manyan kusoshi.

(5) Man shafawa akan lokaci

Lubrication na hanyar tafiya yana da matukar muhimmanci.Yawancin nadi bearings sun "kone su mutu" kuma ba a samo kuɗin ba saboda yatsan mai.An yi imani da cewa wurare 5 masu zuwa na iya zubar da mai: saboda matalauta ko lalacewa O-ring tsakanin zoben da aka ajiye da kuma sandar, mai ya kwarara daga gefen waje na zoben da aka ajiye da kuma sandar;saboda rashin daidaituwa na zoben hatimi mai iyo ko lahani na O-ring, mai yana raguwa tsakanin gefen waje na zoben da rollers (mallaka masu goyan baya, rollers jagora, ƙafafun tuki);saboda ƙarancin O-ring tsakanin rollers (tallafi masu goyan baya, masu jagorar jagora, ƙafafun tuƙi) da bushing, daga bushewa da ruwan mai tsakanin rollers;mai yana zubowa a filogin filler saboda lallausan filo ko lahani ga ramin wurin zama da filogin conical ya rufe;mai yana zubewa tsakanin murfin da abin nadi saboda rashin kyawun zoben O-ring.Don haka, ya kamata ku kula da bincika sassan da ke sama a lokutan yau da kullun, kuma ku ƙara da maye gurbin su akai-akai gwargwadon zagayowar lubrication na kowane sashi.

(6) A duba tsaga

Ya kamata a duba tsagewar tsarin jirgin ƙasa a cikin lokaci, kuma a aiwatar da gyaran walda da ƙarfafawa cikin lokaci.

Lokacin aikawa: Juni-05-2022