Mina shaft :MAterial shine 50Mn high quality carbon tsarin karfe, tare da C abun ciki daga 0.48 zuwa 0.56%, Si abun ciki jere daga 0.17 zuwa 0.37%, Mn abun ciki jere daga 0.7 to 1.0%, S abun ciki jere daga kasa da 0.035%, P abun ciki jeri. daga kasa da 0.035%, da Cr abun ciki daga kasa da 0.25 zuwa 0.30%, Ni abun ciki daga kasa da 0.30%, da Cu abun ciki daga kasa da 0.25% daga cikinsu, Mn wani muhimmin kashi ne a cikin gami karfe, wanda. zai iya inganta ductility da filastik na kayan, tabbatar da isasshen ƙarfi da juriya.Bayan maganin zafi, 50Mn karfe yana da babban ƙarfi da taurin kai, ingantacciyar shigar ciki, zurfin taurin Layer, da kyakkyawan rubutun pearlite, da kyakkyawan aikin injiniya.

Matsayin ƙira don babban shaft yana buƙatar zurfin 2 zuwa 7 mm na hardening Layer da taurin zafin jiki na 50 zuwa 62 HRC.

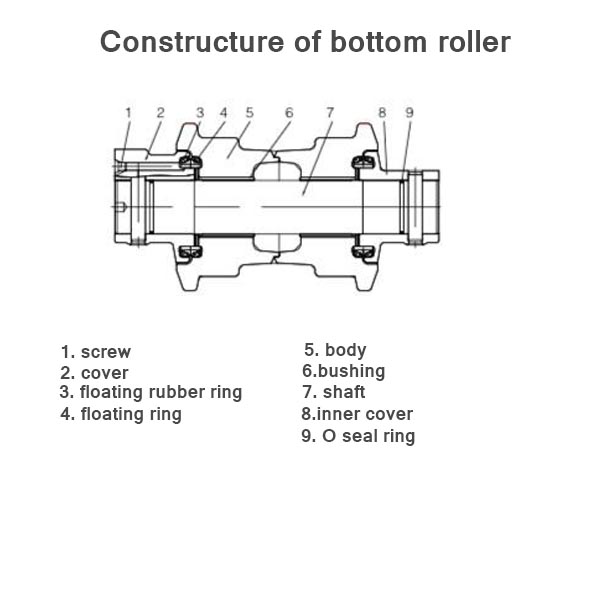

Jiki :Don inganta juriya na lalacewa natabin nadi's jiki, abu shine 40Mn2 alloy tsarin karfe, tare da abun ciki na C daga 0.37 zuwa 0.44%, Si abun ciki daga 0.17 zuwa 0.37%, Mn abun ciki daga 1.4 zuwa 1.8%, P abun ciki daga kasa da 0.030%, da S abun ciki jeri. daga kasa da 0.030%.

The kasa abin nadiAn ƙera jiki tare da tsari mai ƙirƙira.Bayan gyare-gyaren, jikin ƙafar ƙafar yana da zafi don cimma taurin 26-32HRC don kula da babban ƙarfi, filastik, tauri, da kuma aikin injiniya gabaɗaya a cikin jikin motar.The dabaran jiki surface an hõre quenching magani don ƙara taurin da kuma sa juriya na goyon bayan dogo dogo surface.The quenching taurin ne 50-58HRC, tare da zurfin 6-12mm.Wannan yana haifar da kamanni na asali tsakanin taurin saman dogo da taurin haɗin haɗin sarkar (48-58HRC).

Hatimi:Girman girma da rashin ƙarfi na samanO-ringya kamata ya kasance daidai da buƙatun ƙira. Ya kamata a rufe saman mating, kuma ya kamata a tsabtace kowane burrs da gefuna masu kaifi.

Robar hatimi mai iyo da O-zobeya kamata a zaba daga butyl roba mai inganci. Diamita na ciki, girman zaren, elasticity, hardness ( Shore), da gamawar saman ya kamata duk sun bi ka'idodi.Kafin haɗawa, duk abubuwan da ke sama yakamata a bincika su kuma cancanta daidai da ƙa'idodin sama kafin shigarwa.

Tazari :Tsare-tsare tsakanin babban axle da cibiya mai ɗauke da itaabin nadijiki ya zama 0.2-0.4 mm. Lokacin juyawa, kada a kasance tare da toshewamatsalada kyakkyawan aikin rufewa, babu zubar mai.

Lubrication :Mai ɗaukar man a cikinwaƙa roller yakamata a yi allurar ta hanyar amfani da famfo mai. Idan ya cancanta, ana iya ƙara dankon mai mai mai da kyau yadda ya kamata.Kafin a yi amfani da man da ke ɗauke da shi, ya kamata a fitar da man da ba ya daɗe.Sa'an nan kuma, sai a saka sabon mai mai a cikin ramin toshe mai har sai mai ya fita.Lokacin yin allurar mai mai mai, ya kamata a cire madaidaicin hular, kuma a matse ƙarshen mai na na'urar a kan kafada a tashar mai.Ya kamata a sarrafa karfin jujjuyawar filogin mai tsakanin 157-255 Nm.

Lokacin aikawa: Afrilu-05-2023